Quality Assurance | SRN TECH Smart Locks (ISO 9001)

We have a strict quality inspection during each lock production procedures. Ensure every lock is tested well with a good performance before the package.

See how SRN TECH ensures quality: ISO 9001 factory, CE/FCC/RoHS compliance, 30-expert QC team, 100% testing, 2-day proofing, 3-year warranty.

Tests Throughout The Production

Custom Function Development & Fast Iteration

When your project needs go beyond a standard lock, SRN TECH (SRN LOCKS) builds exactly what your site requires. Our 8 dedicated R&D engineers cover firmware, electronics, RF, mobile app, and mechanical design—so you get custom functions, quick prototyping, and monthly product upgrades that keep your solution ahead of the market.

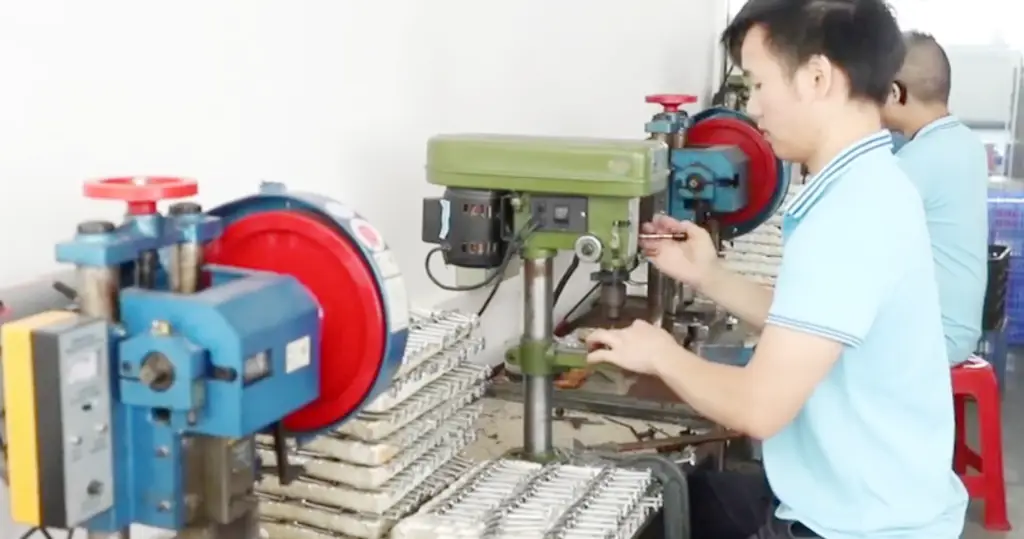

Components Testing

Each small component of our locks is bought from quality, steady raw material factories, and we will test them all before finally using them on our locks.

QC at Every Stage

IQC: material verification; finish thickness, hardness, electronics sampling

IPQC: in-line torque tests, keypad life tests, motor current, RF strength

OQC/Final: 100% function test, battery drain, anti-tamper, packaging integrity

Hardware Part Testing

The hardware part has a big influence on the lock’s final use-life. Each lock hardware part is produced strictly according to our quality demands.

Our Quality System (ISO 9001)

Controlled procedures from sourcing to shipment

Lot traceability, first-article approval (FAI), PPAP on request

Supplier audits & incoming AQL checks

Motherboard Quality & Reliability — What Most Suppliers Overlook

In any smart lock, the motherboard (PCBA) is the brain. It controls RFID/Bluetooth communication, motor drive, sensors, power management, and data security. Because it hides inside the lock body, it’s often overlooked—we don’t. SRN TECH runs a strict hardware/firmware program plus a functional aging test on every production batch to ensure long-term, real-world reliability.

Component sourcing: Approved vendor list (AVL) for ICs, MOSFETs, crystal oscillators, and batteries; lot traceability for each PCBA.

ESD & surge protection: TVS/ESD diodes on signal lines; power rail protection validated to design spec.

RF calibration: Reader power and antenna matching tuned to target read distance and low noise; BLE Tx/Rx verified.

Firmware QA: Secure flashing, checksum validation, boot/reboot stability, and watchdog recovery scenarios.

In-circuit & functional test (ICT/FCT): Jigs verify voltage rails, motor current, keypad matrix, RTC, buzzer/LED, EEPROM logs.

OEM Process (Simple & Fast)

We provide professional logo and number printing on the lock surface, RFID card, and RFID bracelets. Before production, our team will double-check with customers for the design and make sure every step is as total as you need.

Confirm scope – logo placement, serials, manuals, packaging, DND panels, etc.

Free design support – we create print files and dielines; unlimited revisions until approved.

Digital proof – final artwork proof + position map for sign-off.

Sample (optional) – printed pre-production sample if required.

Production – printing/customisation per your PO; in-line QC and final inspection.

Shipment – export-ready packs with carton labels and documentation.

Aging Test

After the lock‘s structure is done, we will do the aging test for over 24 hours. The defect one will be picked up and re-checked.

Reliability Testing

Salt-spray (neutral) corrosion tests

Cycle life (≥200,000 operations by model)

Temperature/humidity chambers; ESD & surge protection checks

Duration & environment: Typical 8–24 hours continuous run; temperature cycling (e.g., 0–50 °C), humidity 20–85% RH as required by model/market.

Load profiles: Repeated lock/unlock motor cycles, RFID scans, BLE sessions, keypad entries, and battery voltage sag events.

Pass criteria: No watchdog resets, no brownouts, stable RF performance, motor current within spec, error log = 0.

Data capture: Each unit’s test ID, firmware build, and measurements are stored; outliers are quarantined for root-cause analysis (8D/CAPA).

Well Delivery

We pack each lock carefully in a master carton and usually ship by DHL, UPS, FedEx, or TNT Express. It usually takes 3-5 days to arrive. Airline and sea shipping are also optional.

What You Receive

2-day proofing, golden samples, mounting templates

3-year warranty + 1% free spare parts

24/7 engineer support, installation videos, and remote debugging

Professional Lock Testing Machines

FAQs

A: Yes. Materials and electronics comply with CE, FCC, and RoHS. Declarations and test reports are available upon request.

A: Each unit passes 100% function tests (mechanical, RF, keypad, power), plus random reliability checks such as cycle life and environmental testing.

Absolutely. We provide certificates, SOP snapshots, AQL plans, and video audits. On-site audits are welcome.

Standard 3-year warranty with 1% free spare parts and lifetime technical support.

Yes. We lock down specifications, finishes, and firmware with approved samples and PPAP/FAI as needed.