As someone who’s always been fascinated by how things work, I recently found myself curious about the process of lock manufacturing.

I mean, we use high-security locks every day to secure our homes, offices, and belongings, but how much do we really know about how they’re made? That’s why I’ve put together this ultimate FAQ guide to give you an in-depth look at the various aspects of lock manufacturing.

Whether you’re a consumer looking to make an informed purchase or an industry professional seeking to broaden your knowledge, this guide is for you.

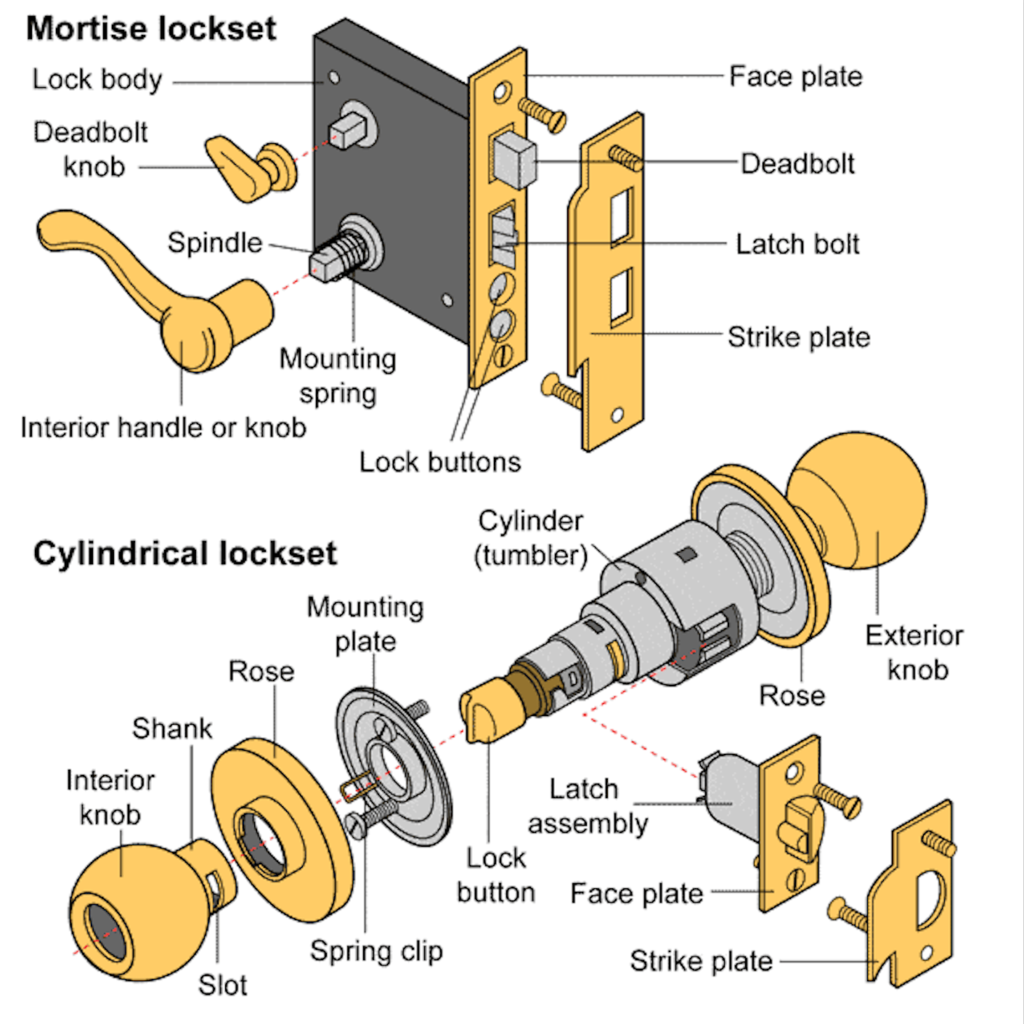

What are the main components of a lock?

Before diving into the manufacturing process, let’s break down the basic components of a lock. Most door locks consist of a lock body, shackle, key, and locking mechanism.

The lock body houses the mechanism and provides the main structure for the lock. The shackle is the U-shaped or looped part of the lock that goes through the object being secured, like a door or gate.

The key is used to operate the lock, and the proper key to the locking mechanism keeps the lock secure.

What are the different types of locks and their manufacturing processes?

There are various types of locks, such as padlocks, deadbolts, lever handle locks, knob locks, and cam locks.

While the manufacturing processes for each type of door lock may differ slightly, the core elements of identical locks are generally the same: producing the lock body, shackle, key, and locking mechanism. The specific manufacturing methods may vary based on the lock’s design and materials used.

What materials are commonly used in lock manufacturing?

Locks are commonly made from metals like brass, steel, zinc, and aluminum. Brass is often used for lock bodies and keys due to its corrosion resistance and machinability. Steel is typically used for shackles and other components that require strength and durability.

Zinc and aluminum are used for their lightweight properties and cost-effectiveness. In some cases, plastics and other materials may also be used, particularly for low-security applications or decorative purposes.

There are a variety of materials used in lock manufacturing, depending on the type of lock and its intended application. Some of the most common materials used in lock manufacturing include:

- Steel: Steel is a strong and durable metal commonly used for making lock bodies and internal components such as springs and pins. It is often coated or plated with other metals such as brass or nickel to improve its appearance and corrosion resistance.

- Brass: Brass is a copper alloy that is often used for making locks due to its corrosion resistance and attractive appearance. It is commonly used for lock bodies, keys, and decorative hardware.

- Zinc: Zinc is a relatively lightweight metal that is often used for making lock components such as lock cylinders and key blanks. It is also commonly used for decorative hardware and coated with other metals such as chrome or nickel for increased durability.

- Aluminum: Aluminum is a lightweight and corrosion-resistant metal that is commonly used for making lock components such as lock bodies and strike plates. It is also commonly used for decorative hardware and coated with other metals for increased durability.

- Plastic: Some locks, particularly padlocks and combination locks, are made entirely or partially of plastic. Plastic is lightweight, inexpensive, and resistant to corrosion, but it is not as strong as metal and may not be suitable for high-security applications.

- Titanium: Titanium is a strong and lightweight metal that is sometimes used for making high-security locks. It is more expensive than other metals but provides exceptional strength and durability.

The specific materials used in lock manufacturing may vary depending on the manufacturer, the type of lock, and the intended application.

What is the process of manufacturing a lock body?

The production of a door lock typically involves several steps, including:

- Design: The first step in door lock production is the design process. This involves creating a blueprint or digital model of the lock that will be produced.

- Material selection: Once the design is complete, the manufacturer must select the appropriate materials to use in the lock’s construction. Common materials include brass, steel, and zinc alloy.

- Casting or forging: The next step is to form the basic shape of the lock body using either casting or forging techniques.

- Machining: Once the lock body is formed, it must be machined to precise specifications to ensure that it will function properly. This step may involve drilling holes for keyways and other components, as well as cutting threads and other features.

- Assembly: After the lock body has been machined, the various components of the lock, including the cylinder, keyway, and tumblers, are assembled and tested.

- Finishing: Finally, the lock is finished using a variety of techniques, including polishing, plating, or painting, depending on the desired appearance and functionality of the lock.

Lock bodies are generally made using either die casting or forging. Die casting involves pouring molten metal into a mold, where it solidifies into the desired shape.

Forging, on the other hand, involves heating the metal to a high temperature and then shaping it using force, such as hammering or pressing. Once the lock body has been formed, it undergoes machining to refine its shape and create any necessary openings or holes.

The lock body is then polished to remove any rough edges or imperfections before being plated and finished.

How are shackles made in the lock manufacturing process?

Shackles are usually made through forging or extrusion. Forging involves heating the metal and then shaping it using force, while extrusion involves forcing the metal through a die to create the desired shape.

After the shackle has been formed, it is cut and shaped to fit the specific lock design. The shackle then undergoes heat treatment to increase its strength and durability, followed by surface finishing, such as polishing or coating, to improve its appearance and corrosion resistance.

How are keys made, and how do they differ for various types of locks?

Key manufacturing starts with the production of key blanks, which are the basic, uncut forms of keys. These blanks are typically made from brass or steel and are shaped through a process called extrusion.

Once the key blanks have been produced, they are cut and finished to match the specific lock type and design. The process of key cutting can vary based on the lock manufacturer and the type of combination lock used, with some requiring more complex cuts and others featuring simpler designs.

What is the process of creating the locking mechanism?

The locking mechanism is at the heart of every lock, and its creation involves designing and manufacturing various components like pins, tumblers, and other internal parts. These components are typically made using machining or molding processes, depending on the material and design requirements.

Once the particular lock order and individual parts have been produced, they are assembled to create the locking mechanism. This assembly is then carefully integrated with the internal mechanisms of the existing lock and body, ensuring a smooth and secure operation.

What quality control measures are used in lock manufacturing?

A quality control station is essential in lock manufacturing to ensure that the final product is reliable, durable, and secure. Some common quality control measures include material testing and inspection to verify the quality and properties of the materials used in the lock.

Dimensional and functional checks are performed on the five tumbler key lock components and assembly to ensure that everything fits and functions as intended.

Additionally, durability, strength, and security tests of key lock pin combinations are conducted to evaluate the mortise lock and key combination’s overall performance. Moreover, the lock manufacturer examines resistance to various types of attacks or stress.

If it manufactures low-security locks, then it considers different quality control measures as opposed to high-security combination locks, mortise locks, or electronic locks.

How has technology impacted the lock manufacturing process?

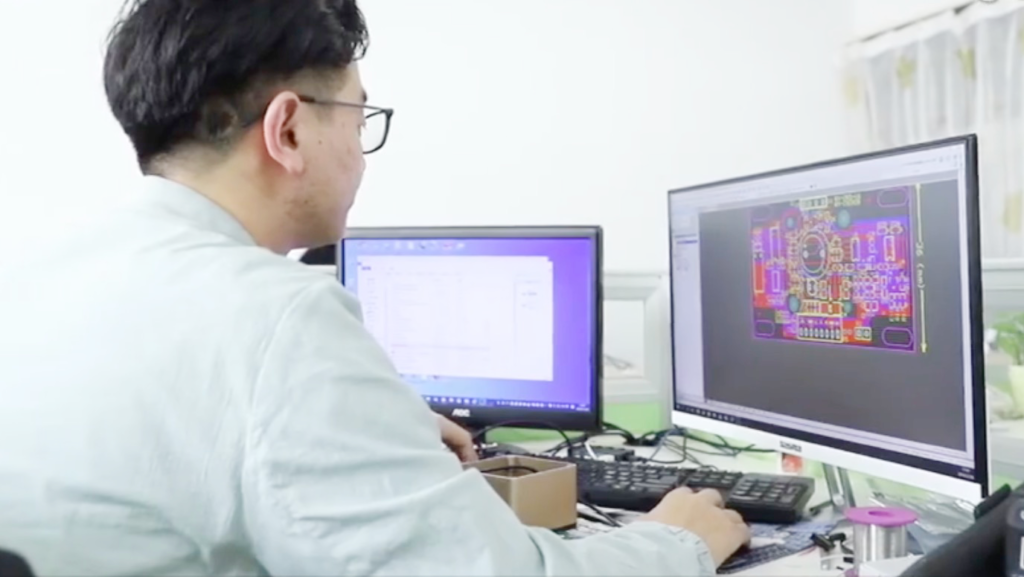

Technology has played a significant role in advancing the lock manufacturing process. Computer-aided design (CAD) and computer-aided manufacturing (CAM) systems allow for more precise and efficient design and production of lock components.

Automation and robotics have streamlined the manufacturing process, reducing labor costs and increasing production speed. Instead of all lock workers sitting in a small area, the process of creating locks is faster than ever.

Furthermore, the development of smart locks and digital security has introduced new materials, designs, high security, and technologies to the industry, offering consumers a wider range of options to secure their property.

What are the environmental considerations in lock manufacturing?

As with any manufacturing process, it’s important to consider the environmental impact of lock production. Some environmental considerations in lock manufacturing include the use of sustainable materials and recycling programs to minimize waste and conserve resources.

Energy-efficient manufacturing processes can help reduce the overall energy consumption and carbon footprint of the industry. Additionally, waste management and pollution control measures should be in place to minimize the impact of manufacturing on the environment.

Once the completed locks are packed, they are sent for shipment.

Conclusion

There you have it – a comprehensive look at the lock manufacturing process and how manufacturers produce locks. I hope this guide has given you a better understanding of how locks are made and the various aspects that go into their production.

By knowing more about the process, you can make more informed decisions when purchasing locks or even just appreciate the craftsmanship and technology that goes into securing our valuables.

I encourage you to continue exploring this fascinating industry and stay informed about the latest advancements in lock technology and manufacturing. SRN, a lock company, is the original equipment manufacturer for all types of locks, including smart locks. Contact us for a start now.